Polyurethane is probably the most versatile polymer but here the focus will be for injections and a long time ago it was found that PU’s are particularly applicable in structures where water leakages are the problem. This product is even today the material that is most known in the field: single component water reactive PU forming, depending on the formulation, a flexible or rigid foam.

Today there are many options:

- 1 or 2C hydrophobic, water reactive PU’s, to stop water in small and big amounts forming a flexible or rigid foam, but it is known today that this way of water stopping may start leaking again.

- Solid PU resins for the second injection (once the water has been stopped or reacted away) to create a permanent seal of the leakage.

- A hydrophilic 1 or 2C water-soluble PU system forming, with the water in the structure and over a wide range (up to 1: 10), a flexible PU hydrogel.

- PU systems with a dual performance: in case there is water it will after the reaction with water foam and once the water is stopped or reacted away a solid resin will be formed to create a permanent seal.

There are numerous applications in this field where the PU’s as mentioned above can be used: crack repair, stopping small or heavy leaks, joint repair, curtain grouting, soil stabilization (restoring strength or waterproofing), usage of injection hoses in new constructions, etc.

All these products, as mentioned before, are in the Ecmas PU injection program and manufactured in India. Besides the systems, Ecmas is able to formulate tailor-made systems to fulfill the requirements on the job site.

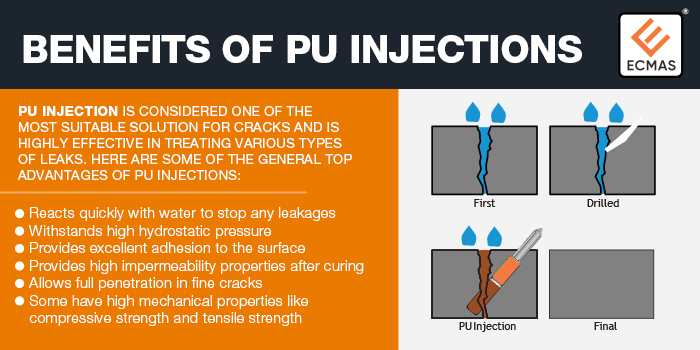

Cracks are a frequent issue in all types of concrete structures, but if they are not fixed, they can develop into more serious issues like leaks, which can seriously harm the property and its value.

Besides cracks in concrete structures, there are a lot of other sites where the PU fills voids between aggregates or behind walls like for tunnels, basements (eventually to repair a broken membrane), etc.

In most of cases, there is water available or a problem and then PU is the good choice to resolve the problem permanently. The right product is in the right place.

PU injection is a waterproofing technique that involves injecting a polyurethane system into cracks or openings in concrete structures to stop water leakage or in any other leaking structure or to restore strength. Useless to say that every application needs its own injection technique but more important: choosing the right material. The right product is in the right place.

Ecmas has the expertise to help you in this matter

Types of PU Injection systems

Besides the different inorganic and organic (epoxy, acrylates, etc) injection systems polyurethane waterproofing systems are typically separated into four types:

PU Injection Foam (EcmaGrout PU F series)

PU injection F series forms, after the reaction with water, a flexible or rigid foam. After the water is stopped the crack needs to be repaired with a resin system out of the PU R series to create a permanent sealing.

These are highly useful in applications with high hydrostatic pressure, like dams, bridges, and tunnels.

PU Injection Resin (EcmaGrout PU R series)

These are the most commonly used types for PU injection when no water is involved and there are two options: flexible or structural repair. Cracks repaired with these PU injection R systems remain leak-proof in case of cracks with restricted width and exposed to dynamic stress.

PU Multi Injection (EcmaGrout PU M series)

This PU M series is basically a system that has the features from the PU F series and the PU R series in one product. When there is water the PU will react it away under forming a flexible or structural PU foam and once the water has been stopped or reacted away after injection with the same pump, same material, and the same packer it will form a solid flexible of structural PU creating a permanent seal.

PU Injection Gel (EcmaGrout PU G series)

This series of PU injection systems is based on a hydrophilic, low viscous component that forms, after the reaction with water present in the structure, a PU gel (hydrogel). The system as such takes up to 1: 10 with water and the reaction time is short. Typical applications for these product G series are: shutting off heavy water leakage, making soil waterproofed by filling the voids, and curtain grouting by filling the voids behind a wall, as injection material for the usage of the injection hose.

ECMAS Construction Chemicals is the leading manufacturer of PU Injection products in India and offer different types of polyurethane grouting materials like foam, gel, resin, and multi-injection grout. Visit www.ecmas.in today to know more about our products or contact us.