Concrete is the most common material used for construction projects due to its ability to mould into any shape. As it is a key construction material, it should have sufficient strength to withstand heavy loads and footfall. Thus, it is important to ensure that the concrete used for construction has the required strength and structural integrity.

Synthetic structural fibers are made up of a non-fibrillated monofilament containing a unique blend of fibrillated Polypropylene fiber and Polyolephinic polymers. These fibers are designed to improve concrete’s mechanical and durability properties, minimize plastic shrinkage, and increase its ductility, flex fatigue and fatigue resistance.

For both the areas, three types of waterproofing solutions are incorporated:

Effect on early age concrete

Volume changes in the early age of concrete lead to weakened planes and micro-cracks due to stress that exceeds the concrete strength at a particular time. These cracks can be prevented through the blocking action of such synthetic fibers.

As the fibers are dispersed uniformly throughout the concrete, it hinders the development of large capillaries that are generally caused by water bleeding into the surface.

Effect on hardened concrete

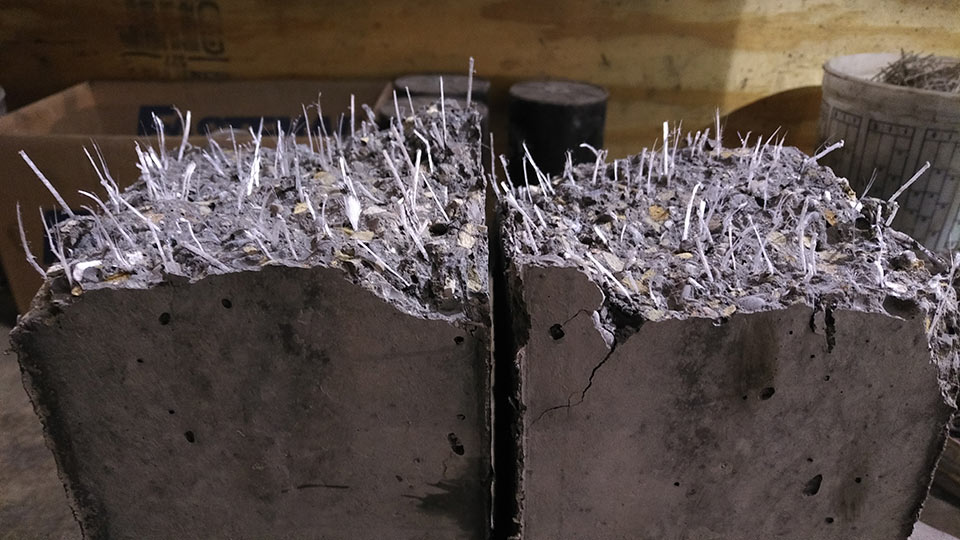

The benefits of synthetic fibers in the early age of concrete continue to the hardened concrete. Moreover, they also lead to lowered permeability along with resistance against abrasion and shattering & impact forces.

The ability of hardened concrete to withstand shattering forces is greatly augmented through the use of synthetic structural fibers, compared to plain concrete, which shatters at the very first impact.

Abrasion resistance is gained by concrete upon the addition of synthetic fibers as the water-cement ratio isn’t decreased by variable bleed water.

ECMAS provides a synthetic structural fiber called ECMAS EXF 54 that is designed to minimize and, in some cases, eliminate plastic shrinkage. Unlike metal fibers, ECMAS EXF 54 is a non-corrosive, non-magnetic, and completely acid & alkali-proof solution. It guarantees uniform performance thanks to the excellent dispersion of fibers in the mix while maintaining the same mix workability.